Ever wondered what makes the powerful Paccar MX-13 engine tick? Its robust design and impressive performance have made it a popular choice for heavy-duty trucking applications, but understanding the intricate network of its parts can be a challenge. This in-depth guide will take you on a journey through the heart of the MX-13 engine, unveiling the secrets behind its functionality and shedding light on the key components that contribute to its remarkable power and efficiency.

Image: sidhartharoshni.blogspot.com

Whether you’re a seasoned mechanic, a curious truck enthusiast, or simply someone looking to unravel the engineering marvels that drive modern transportation, this comprehensive breakdown of the Paccar MX-13 engine parts diagram will equip you with the knowledge to appreciate the complexities of this remarkable engine.

The Foundation: Understanding the Paccar MX-13 Engine

A Legacy of Power and Efficiency

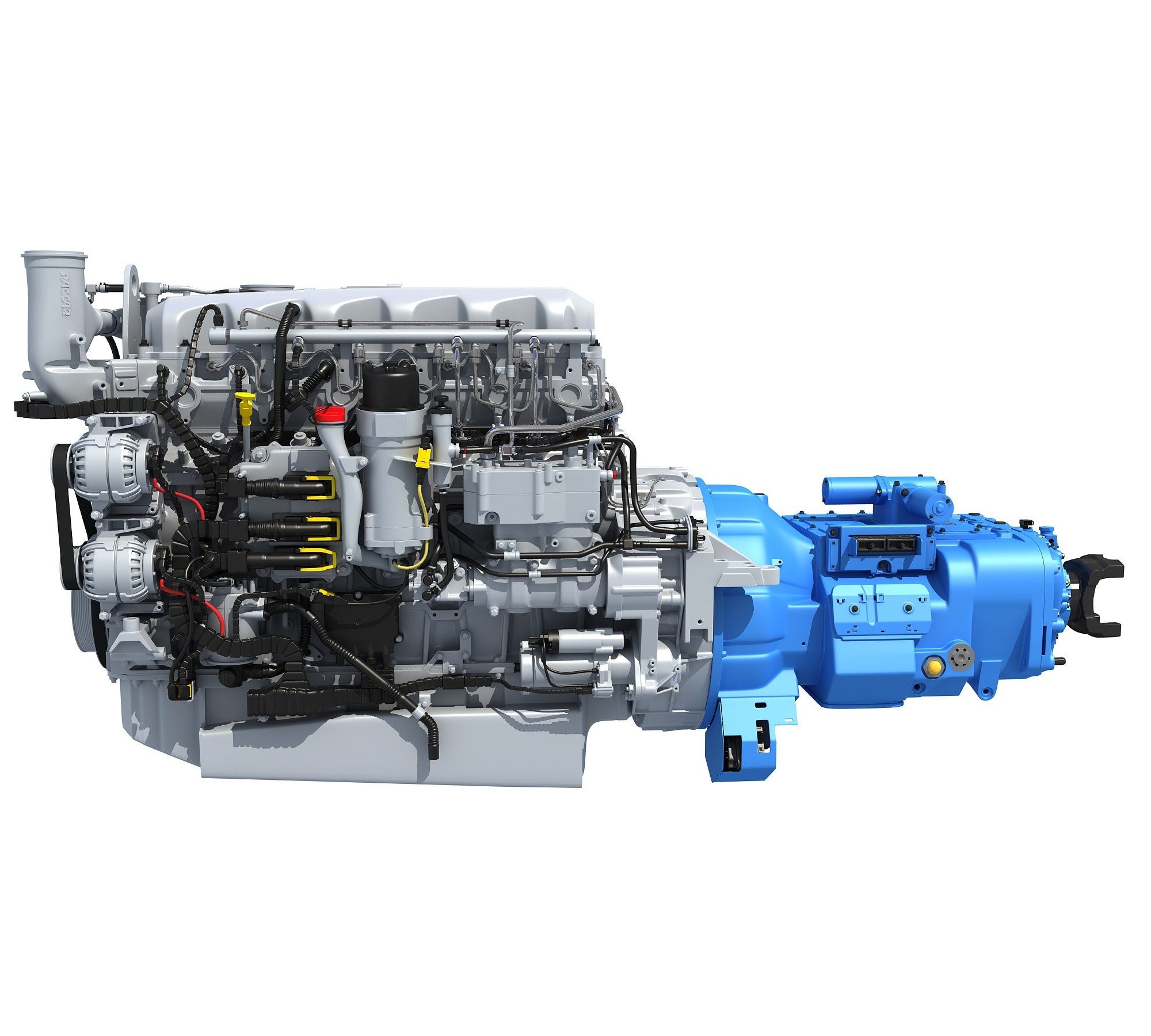

The Paccar MX-13 engine is a testament to the unwavering commitment to engineering excellence that has defined the Paccar brand. First introduced in 2007, the MX-13 quickly became the cornerstone of power and efficiency for heavy-duty trucks, exceeding expectations in performance and durability. This engine has become a defining factor in the trucking industry, thanks to its ability to deliver exceptional torque and horsepower, while maintaining a remarkable fuel economy. It’s a true workhorse that’s built to withstand the rigors of demanding driving conditions.

A Closer Look at the MX-13’s Design

To understand the Paccar MX-13, it’s essential to grasp its fundamentals. The engine is a 12.8-liter, six-cylinder, in-line engine that boasts a sophisticated design. Unlike traditional V-shaped engines, its in-line configuration provides a more compact layout and a lower center of gravity, contributing to improved stability. The MX-13 incorporates advanced features like electronic controls, variable-geometry turbochargers, and a highly efficient common rail fuel injection system, all working in harmony to deliver optimal performance and fuel efficiency.

Image: detoxicrecenze.com

Delving Deeper: Exploring the Paccar MX-13 Engine Parts Diagram

1. The Crankshaft: The Heart of the Engine

At the heart of every engine lies the crankshaft. This robust steel component is the engine’s primary rotating shaft, converting the reciprocating motion of the pistons into rotary power that drives the wheels. The crankshaft connects to the pistons via connecting rods, ensuring that the linear motion of the pistons is efficiently transformed into rotational energy. The Paccar MX-13’s crankshaft is designed for exceptional durability, able to withstand the immense forces generated by the engine under heavy loads.

2. Pistons and Connecting Rods: The Power Stroke

The pistons are the key components that convert the combustion pressure within the cylinders into linear motion. The reciprocating motion of the pistons is transferred to the crankshaft via connecting rods – a crucial link in the power transmission chain. The Paccar MX-13 utilizes forged steel pistons engineered for optimal performance and longevity. They are designed to handle high combustion pressures and temperatures while minimizing wear and friction.

3. Cylinders and Cylinder Heads: Combustion Chamber

The cylinders form the core of the combustion process, housing the pistons and providing a space for the combustion of fuel and air. The cylinder head sits atop the cylinder block, incorporating the valve train, which controls the flow of air and exhaust gases. The Paccar MX-13 engine utilizes high-strength cast iron cylinders with durable cylinder heads to ensure long life and resistance to the severe pressures and temperatures generated during combustion.

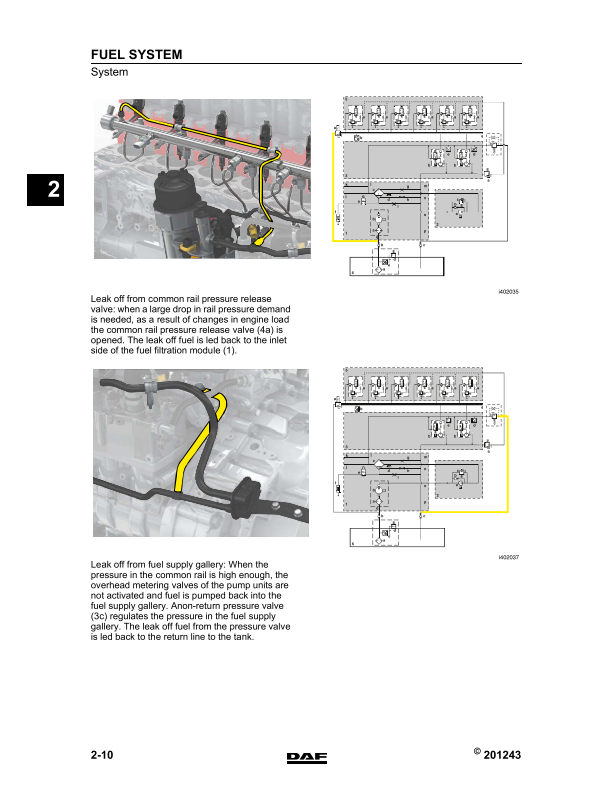

4. Fuel System: Delivering the Power

The fuel system is responsible for delivering the precise amount of fuel to the cylinders at the optimal time for combustion. The MX-13 engine features a sophisticated common rail fuel injection system, which provides high-pressure fuel injection for precise fuel delivery and optimal combustion. The system utilizes a high-pressure pump to inject fuel into a common rail, from which it is then precisely delivered to each cylinder via injectors, resulting in efficient combustion and reduced emissions.

5. Turbocharger: Boosting Performance

The turbocharger plays a critical role in enhancing the engine’s power output and fuel efficiency. It utilizes exhaust gases to drive a turbine, which boosts the amount of air flowing into the cylinders. The Paccar MX-13’s turbocharger is carefully engineered to provide optimal boost levels across the engine’s operating range, maximizing power and torque while minimizing fuel consumption.

6. Cooling System: Managing Heat

The cooling system is crucial for maintaining the engine’s operating temperature within optimal limits, preventing overheating and ensuring maximum engine performance and durability. The Paccar MX-13’s cooling system utilizes a combination of a radiator, water pump, and various other components to efficiently dissipate heat from the engine.

7. Exhaust System: Managing Emissions

The exhaust system removes the exhaust gases from the cylinders, transporting them into the atmosphere. However, modern engines are equipped with emission control systems to significantly reduce pollutants in the exhaust gases. The Paccar MX-13 engine features advanced emission control technology, including a selective catalytic reduction (SCR) system, to minimize emissions and comply with strict environmental regulations.

Maintenance and Repair: Keeping the MX-13 Engine Running Strong

Maintaining a Paccar MX-13 engine involves adhering to a regular maintenance schedule that includes oil changes, filter replacements, and inspections of key components. This preventative maintenance ensures optimal engine performance and longevity. When repairs are needed, it’s crucial to rely on qualified technicians who are familiar with the engine’s intricacies and have access to genuine Paccar parts.

Paccar Mx 13 Engine Parts Diagram

Conclusion: Unlocking the Power of the Paccar MX-13

Understanding the intricate parts diagram of the Paccar MX-13 engine unveils a world of engineering excellence and innovation. From the crankshaft’s rhythmic rotation to the fuel system’s precise fuel delivery and the turbocharger’s power boost, each component plays a vital role in delivering the engine’s impressive performance. This article has provided a comprehensive exploration of the MX-13’s inner workings, empowering you with a deeper understanding of this iconic engine. Whether you’re involved in the trucking industry or simply fascinated by the mechanics of powerful engines, the Paccar MX-13 serves as a testament to the capabilities of human ingenuity.