Ever heard of SFA on a motor? It might sound like something out of a science fiction novel, but it’s actually a common term in the world of electrical motors. While you might not encounter it in everyday life, understanding SFA can be crucial for professionals working with motors, technicians troubleshooting electrical issues, and even those interested in the inner workings of these essential machines.

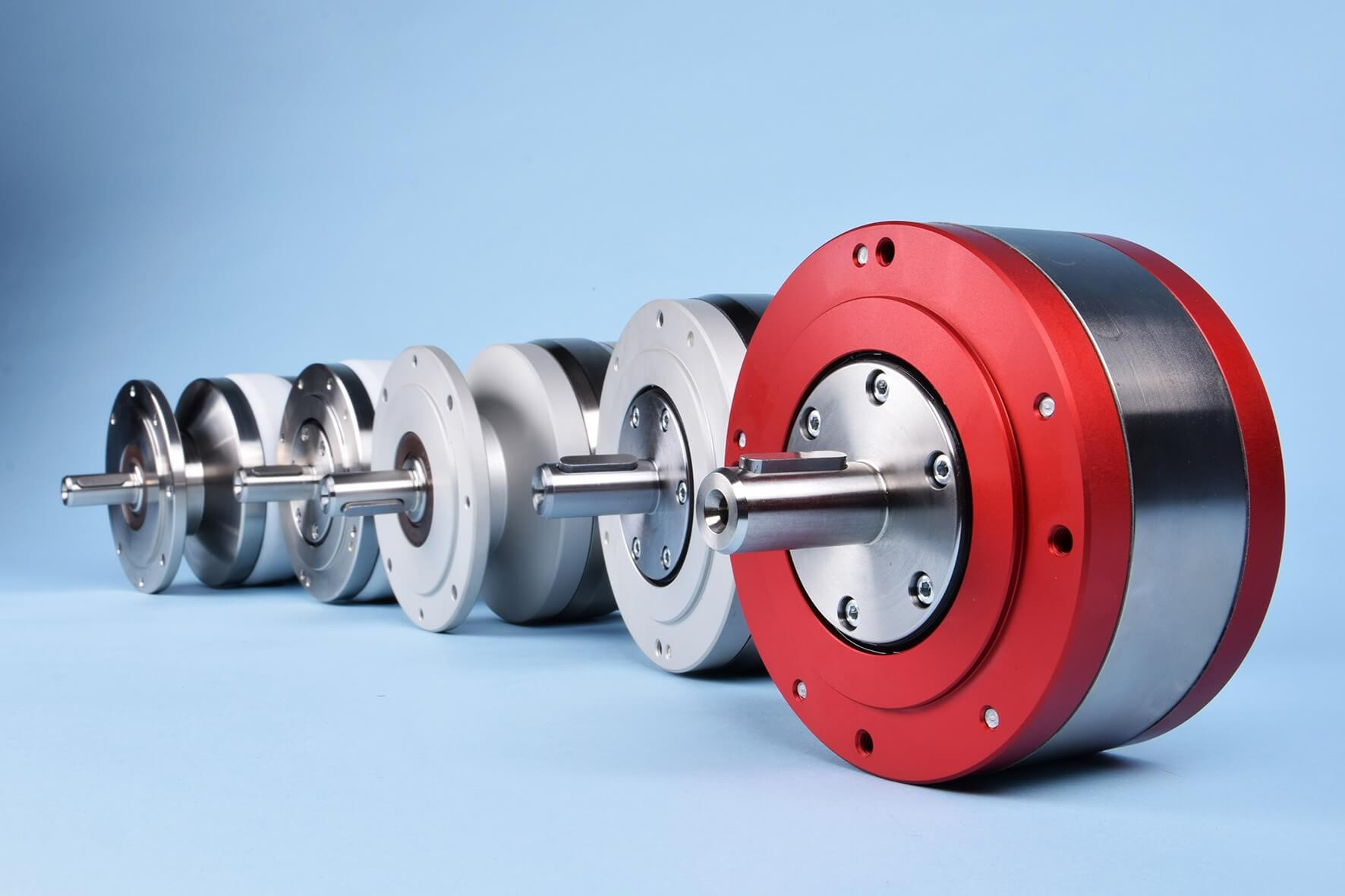

Image: www.catawiki.com

Imagine working on a large industrial motor, a vital part of a manufacturing process. You notice a strange humming sound, and the motor seems to be struggling. With a quick check of the motor’s data, you discover the SFA is exceeding the safe limit. Now, you have an understanding of what the issue might be, and you can take the appropriate steps to fix it.

Delving into the World of SFA

SFA stands for “slip frequency”, and it’s a critical parameter that helps us understand the performance and health of an electrical motor.

In simple terms, slip frequency represents the difference between the synchronous speed of the motor (the theoretical speed at which the motor would rotate if there were no losses) and the actual speed of the motor’s rotor. This difference is measured in Hertz (Hz) and indicates the amount of slip happening within the motor.

Understanding Slip Frequency in Detail

The concept of slip frequency is deeply intertwined with the working principle of induction motors, the most common type of electric motor used in industries worldwide. Induction motors rely on the principle of electromagnetic induction, where a rotating magnetic field is created by stator windings. This field induces currents in the rotor, creating torque and causing the rotor to rotate.

However, the rotor never quite reaches the same speed as the rotating magnetic field. This difference in speed is due to various factors, including the load on the motor, the frequency of the power supply, the design of the motor, and other factors that cause losses within the system. The resulting difference in speed is known as slip and is expressed as a percentage or in Hertz as slip frequency.

A higher slip frequency typically indicates a heavier load on the motor, increased losses, or even a potential problem in the motor’s operation. Monitoring SFA allows technicians to identify potential issues with the motor and take corrective actions, ensuring efficient and reliable operation.

Interpreting SFA: A Guide for Motor Professionals

SFA provides valuable insights into the motor’s condition. Monitoring this parameter allows us to understand:

- Motor Loading: A high SFA indicates a high load, while a low SFA signifies a light load.

- Motor Efficiency: A higher SFA generally means lower operating efficiency due to increased losses in the motor.

- Potential Issues: An abnormally high SFA could indicate problems like rotor winding problems, blocked bearings, or even an unbalanced load on the shaft.

While a small amount of slip is expected and normal, excessive slip can lead to overheating, reduced efficiency, and even motor damage. Therefore, keeping a close eye on SFA is essential for optimal motor operation and longevity.

Image: www.im-tek.com

SFA in the Digital Age: Trends and Developments

In today’s digitally driven world, the monitoring and management of motors are becoming increasingly sophisticated, with SFA playing a crucial role.

Modern motor control systems and smart sensors allow for real-time monitoring of SFA and other critical motor parameters. This data can be analyzed to detect potential issues early, predict motor failure, and optimize motor performance. This is not only improving motor efficiency but also contributing to reduced downtime and increased productivity.

Tips for Optimized Motor Performance Based on SFA

Here are some tips for optimizing motor performance based on your understanding of SFA:

- Regularly Monitor SFA: Make SFA monitoring a routine practice, especially for critical motors that power your operations.

- Analyze SFA Trends: Don’t just look at the current SFA value. Analyze trends over time to identify potential issues before they become major problems.

- Establish Thresholds: Define acceptable SFA ranges for your specific applications. This allows you to proactively address any concerning changes.

- Consider Motor Upgrades: If you need to handle heavier loads or improve efficiency, explore motor replacements or upgrades to achieve optimal SFA levels for your needs.

FAQs on SFA

Here are some frequently asked questions about SFA:

What is a normal SFA value?

The normal SFA value can vary depending on the motor type, design, and load conditions. However, a typical range for a healthy motor would be between 1 Hz and 4%.

How do I measure SFA?

You can use specialized motor analyzers or devices equipped with slip frequency measurement capabilities. Some modern motor control systems also provide SFA readings as part of their monitoring functionalities.

Can I adjust SFA?

You can’t directly adjust SFA, but you can influence it by factors like controlling the load, maintaining optimal motor operating conditions, and ensuring a healthy motor with minimal mechanical issues.

What Is Sfa On A Motor

Conclusion

Understanding slip frequency (SFA) is crucial for anyone working with electrical motors. By monitoring SFA, identifying trends, and addressing any issues early, you can optimize motor performance, improve efficiency, and prevent costly downtime. You can also learn more about advanced motor control systems and smart sensors that offer real-time SFA monitoring and analysis.

Are you interested in exploring further the role of SFA in motor performance optimization? Let’s keep the conversation going! Share your thoughts, questions, or experiences in the comment section below.