Imagine a factory floor bustling with life, machines whirring, and production at its peak. This intricate dance of automation is powered by the unseen force of electricity, channeled through cables, serving as the lifeblood of industry. But what happens when these cables become strained, unable to handle the relentless demand of powerful motors? The answer lies in precise calculations, ensuring the right cable size for every motor, a feat made possible by the 3 phase motor cable size calculator.

Image: www.176iot.com

The 3 phase motor cable size calculator is a vital tool for electricians, engineers, and anyone involved in industrial applications. It acts as a silent guardian, ensuring that the flow of electricity to your motors is efficient, reliable, and safe. This article delves deep into the world of 3 phase motor cable size calculators, uncovering the how, why, and what behind these indispensable tools.

Understanding the Need for Precise Calculations

The heart of the industrial world beats with the rhythm of powerful 3 phase motors, driving pumps, compressors, conveyors, and countless other essential machinery. These motors are designed to harness the energy of three alternating currents, each offset by 120 degrees, delivering a smooth and powerful rotation. But this power comes with a price – the risk of overheating, voltage drops, and even catastrophic failures if the cable carrying this electricity is not sized correctly.

Imagine a garden hose attempting to deliver the flow of a powerful fire hose. The thin hose would buckle under the pressure, potentially causing leaks and damage. Similarly, a 3 phase motor connected to inadequate cabling can lead to overheating, reduced efficiency, and potential fire hazards. This is where the 3 phase motor cable size calculator steps in.

The Science Behind the Calculator: Demystifying the Formula

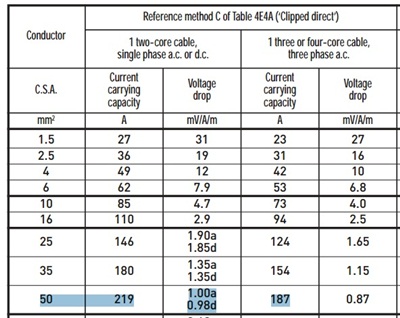

At the core of the 3 phase motor cable size calculator lies a formula, meticulously derived from electrical engineering principles. This formula takes into account various factors, each playing a crucial role in determining the appropriate cable size. Let’s break down these components:

-

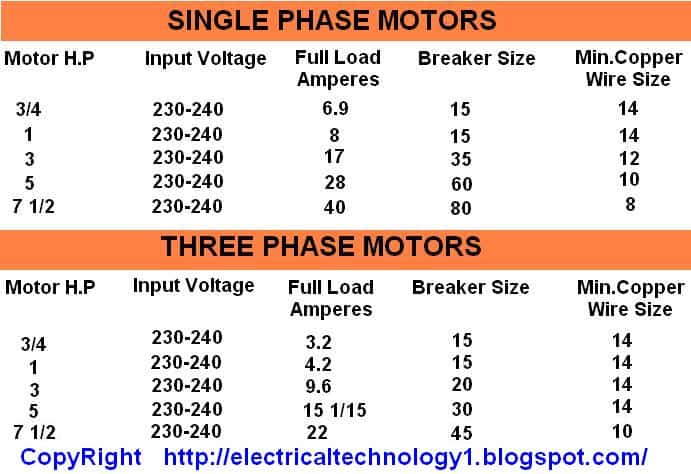

Motor Power (kW or HP): This is the fundamental starting point, representing the amount of power the motor consumes from the electrical supply. The higher the horsepower, the greater the load on the cable.

-

Voltage (Volts): This defines the electrical potential driving the current through the cable. Higher voltage allows for smaller cables to carry the same amount of power, but also necessitates stronger insulation for safety.

-

Current (Amps): This represents the actual flow of electrons through the cable, directly proportional to the power and inversely proportional to the voltage. Determining the current is paramount for accurate cable sizing.

-

Distance (Meters or Feet): This factor accounts for the length of the cable run from the power source to the motor. As distance increases, so does the resistance of the cable, potentially causing voltage drops and reduced efficiency.

-

Ambient Temperature (°C or °F): The surrounding temperature influences the heat dissipation from the cable, impacting the maximum current it can safely carry.

-

Load Factor: This factor accounts for the expected duration of the motor’s operation. Continuous duty cycles require larger cables compared to intermittent operation.

The calculator elegantly integrates these variables into a formula, factoring in the properties of copper or aluminum conductors, incorporating safety margins, and ultimately recommending the appropriate cable size to ensure safe and efficient operation.

Beyond the Formula: Understanding Cable Types and Selection

While the formula provides the backbone of cable sizing, the real world throws in a plethora of factors that must be considered. The type of cable chosen is critical, influenced by factors such as:

-

Conductor Material: Copper is the most common conductor material due to its low resistance and excellent conductivity, but aluminum is a viable alternative for larger cables.

-

Insulation Type: The insulation material must be appropriate for the voltage and ambient temperature, ensuring safety and preventing electrical shorts.

-

Number of Cores: A 3 phase motor requires three conductors for the phases, plus a neutral conductor and potentially an earth wire for grounding.

-

Cable Armor or Sheathing: Applications with high mechanical stress require cable armor (steel braiding) or sheathing (PVC or rubber coating) for added protection.

-

Installation Conditions: Ambient temperature, moisture levels, potential physical damage, and other environmental factors play a role in cable selection.

Image: www.electricaltechnology.org

Utilizing the 3 Phase Motor Cable Size Calculator: A Step-by-Step Guide

Navigating the complexity of cable sizing can seem daunting, but the 3 phase motor cable size calculator offers a simple and user-friendly solution. Many online platforms and software applications provide interactive calculators, guiding you through a step-by-step process. Here’s a common approach:

-

Input Motor Data: Enter the motor’s power rating (kW or HP), voltage, and type of duty cycle (continuous or intermittent).

-

Specify Cable Distance: Enter the distance between the power source and the motor.

-

Select Cable Type: Choose the conductor material (copper or aluminum), insulation type, number of cores, and any required armor or sheathing.

-

Calculate Cable Size: The calculator will process this information and automatically recommend the appropriate cable size, often expressed using the cross-sectional area of the conductor, typically in square millimeters or square inches.

-

Review Results: The calculator typically provides additional insights, including potential voltage drops, temperature rises, and safety considerations.

Expert Insights and Practical Tips for Success

The world of cable sizing is complex, and the calculator is merely a powerful tool in your arsenal. Here are valuable insights from experienced electricians and engineers:

-

Always double-check: The results from the calculator are just a starting point. Verify the recommended cable size against industry standards and local electrical codes.

-

Factor in safety margins: It’s always prudent to select a slightly larger cable size than initially calculated to provide a buffer for future upgrades or unforeseen load increases.

-

Seek expert assistance: Consult with a qualified electrician or engineer for complex installations or situations requiring specialized knowledge.

3 Phase Motor Cable Size Calculator

https://youtube.com/watch?v=Qj3Bh3bwjxU

Conclusion: Harnessing the Power of Knowledge

The 3 phase motor cable size calculator is not just a tool but an indispensable ally, ensuring that your motors operate safely, efficiently, and reliably. By understanding the science behind the calculations, the intricacies of cable selection, and the value of expert advice, you can navigate the complexities of industrial electricity with confidence.

This article has shed light on the vital importance of precise cable sizing, empowering you to make informed decisions, ensuring the smooth flow of electricity, and driving productivity forward. Embrace the knowledge, apply the tools, and let your machines shine!