You’re in the middle of a construction project, and you need to choose the perfect I-beam. You’ve got the blueprints, the calculations, but you’re staring at a bewildering array of I-beams with different sizes and weights. How do you know which one is right for your needs? You need a tool to help you understand those numbers, and that’s where an I-beam size and weight chart comes in.

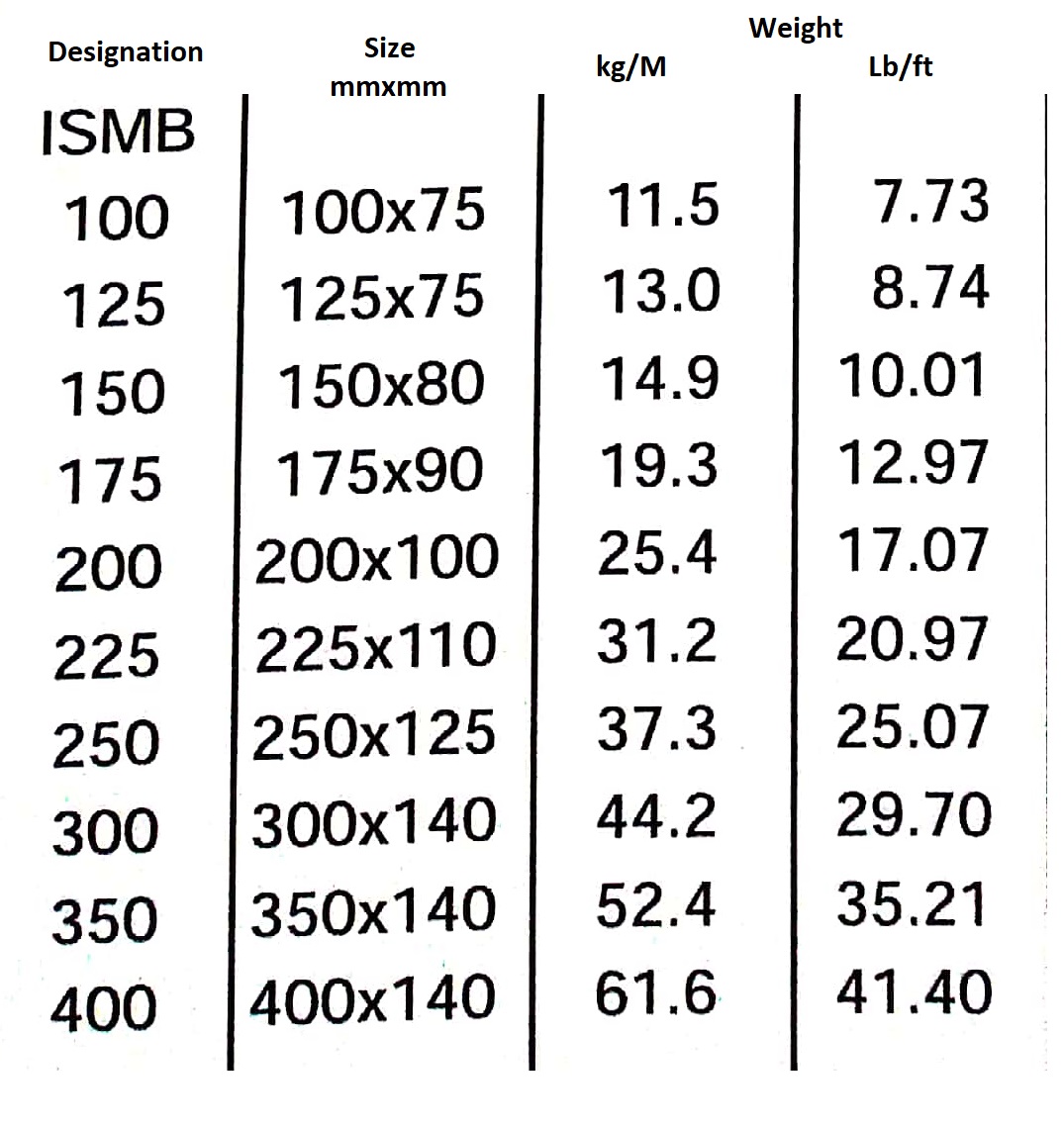

Image: brandonkss.github.io

Imagine, for a moment, building a sturdy bridge. You need the right I-beams to hold up the heavy weight of traffic, and you need to be certain they won’t buckle under pressure. A chart that clearly displays the load-bearing capacity of different I-beam specifications is essential to getting this crucial step right. Whether you’re a seasoned engineer or a DIY enthusiast, understanding I-beam sizes and weights is a fundamental skill.

What is an I-Beam, and Why is it so Important?

An I-beam, also known as an H-beam, is a structural element shaped like the letter “I.” It’s a highly versatile and robust beam design commonly used in construction, engineering, and other heavy-duty applications. Its unique shape maximizes its strength while minimizing its weight. The horizontal flanges at the top and bottom provide the load-bearing capacity, while the vertical web acts as a stabilizing force, distributing the load effectively.

The popularity of I-beams stems from their exceptional strength-to-weight ratio. The I-beam’s design enables it to withstand significant strain without compromising its structural integrity. This makes it ideal for a wide range of building projects where its load-bearing capabilities are crucial, including bridges, buildings, and industrial structures.

Understanding I-Beam Specifications: A Key to Making Informed Choices

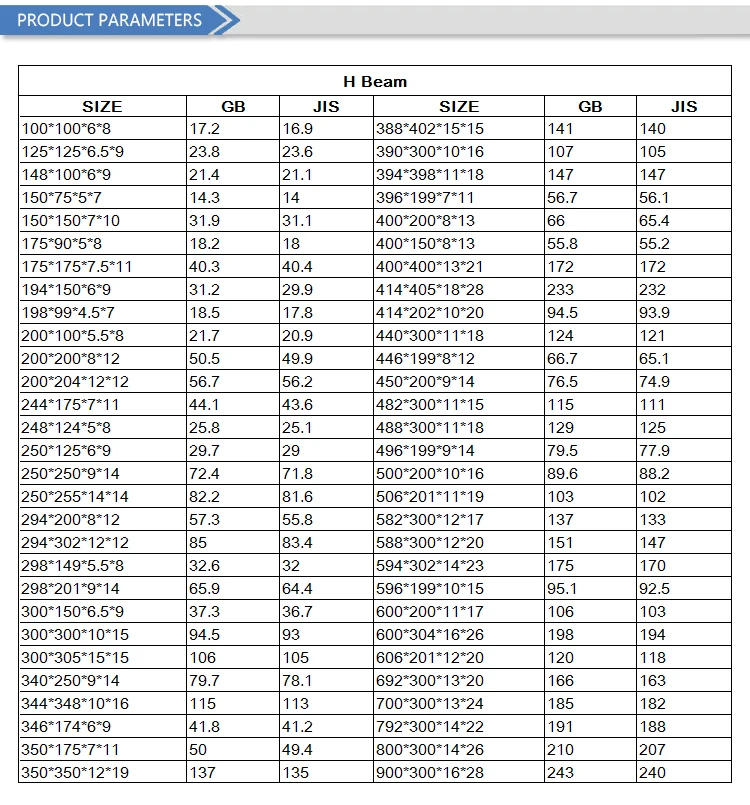

The I-beam size and weight chart is your go-to resource for understanding the critical specifications of each I-beam. It typically displays information such as:

- Size: I-beams are classified by their nominal depth, which is the distance between the top and bottom flanges. Common sizes range from 4 inches to 36 inches or more.

- Weight Per Foot: This value represents the weight of a one-foot segment of the I-beam. It is crucial in determining the overall weight of the structure and selecting the appropriate support system.

- Flange Width: This measurement refers to the width of the top and bottom flanges. The wider the flanges, the greater the load-bearing capacity of the beam.

- Web Thickness: The vertical web between the flanges determines its stability and resistance to bending. A thicker web generally indicates a more robust I-beam.

- Material: I-beams are typically made from steel, but other materials such as aluminum or wood can also be used. The material type affects the overall weight and load-bearing capacity.

Reading and Interpreting the I-Beam Chart

An I-beam size and weight chart is organized in a systematic way to make it easy to find the information you need. However, it’s essential to be familiar with the different elements of the chart to accurately interpret the data.

Most I-beam size and weight charts are formatted in a grid or table format, with columns representing specific size parameters like depth, flange width, web thickness, and material type. The rows correspond to different I-beam sizes and weight per foot. This standardized format allows for quick and efficient comparison of various I-beam options.

Image: tupuy.com

Determining the Right I-Beam for Your Project

Selecting the right I-beam for your project requires a careful consideration of several factors:

- Load: This represents the weight or force that the I-beam needs to support. Determine the maximum weight the beam will carry, including both the structure’s weight and any additional loads it might encounter.

- Span: Span refers to the horizontal distance between the supports for the beam. The longer the span, the more stress the beam will experience.

- Code Requirements: Local building codes and industry standards often dictate the minimum requirements for I-beam sizes, based on the specific application and load capacity. Always ensure your choice adheres to these regulations.

- Budget: Cost is also a crucial consideration. Some I-beams are more cost-effective than others, depending on their size, material, and availability. Choose an I-beam that balances performance with affordability.

Using the I-Beam Chart to Make Critical Decisions

After considering these factors, you are ready to use the I-beam size and weight chart to select the optimal beam for your needs:

- Find the Appropriate Section: Use the chart’s columns to locate the desired material type (steel, aluminum, or other) and any specific specifications for web thickness and flange width if required.

- Locate the I-Beam Size: Begin by looking at the chart’s rows, paying attention to the depth of the I-beams. Identify the beam depths that meet your project’s span and load requirements.

- Check Weight Per Foot: While you’re reviewing the chart’s rows, ensure that the I-beam’s weight per foot is manageable for your chosen support system.

- Compare Options: Use the chart to compare different I-beam sizes and weights to determine the most suitable one for your project.

Experts’ Advice: Tips for Choosing the Right I-Beam

When navigating the world of I-beam sizes and weights, it’s a good idea to seek expert advice. Experienced engineers and contractors can provide valuable insights and help you avoid common mistakes.

Here are some tips from industry professionals:

- Overestimate Load Capacity: It’s always better to err on the side of caution. A slightly larger I-beam will provide peace of mind and ensure the structure’s longevity.

- Factor in Future Expansion: If there’s a chance you’ll need to add more load in the future, it’s a good idea to select an I-beam with a greater load capacity than initially required.

- Consult Local Codes: Always check the latest building codes and regulations in your area to ensure that your chosen I-beam meets the minimum standards for safety and structural integrity.

FAQs: I-Beam Sizes and Weights

Q: How do I find an I-beam size and weight chart?

A: There are multiple sources for I-beam charts. Many construction supply companies and online resources provide these charts. Additionally, engineering handbooks and online databases are great resources for comprehensive information about I-beams.

Q: What are the units of measure for I-beam size and weight?

A: I-beam size is typically measured in inches (depth and flange width) and weight per foot is usually expressed in pounds per linear foot (lbs/ft).

Q: Is there a specific unit for I-beam weight?

A: The most common unit for I-beam weight is pounds per linear foot (lbs/ft). However, weight can also be expressed in kilograms per meter (kg/m).

Q: Can I calculate I-beam weight based on its size?

A: Yes, you can use specific formulas to calculate an I-beam’s weight based on its dimensions. However, it’s often easier and more accurate to consult a readily available chart that provides pre-calculated weight values.

Q: Are all I-beams the same shape?

A: While the basic “I” or “H” shape is common, there are variations in the flange shape. Some I-beams have curved flanges or wider flanges at the bottom for specific applications.

I Beam Size And Weight Chart

Conclusion

Understanding I-beam sizes and weights is crucial for anyone involved in construction or engineering projects. To make informed decisions about structural components, you need a reliable I-beam size and weight chart. This chart is a valuable tool that provides essential data for selecting the right I-beam for any specific application. By using this guide and heeding expert advice, you can choose the perfect I-beams for your project and ensure a strong and durable construction.

Are you working with I-beams in your next project? Tell us about your experiences in the comments below! We’d love to hear about your I-beam selection challenges and how you use the I-beam size and weight chart to get the job done right.