Have you ever wondered about the intricate machinery responsible for delivering precisely metered fuel to your diesel engine? It’s a marvel of engineering, and the Stanadyne DB4 injection pump, often seen in classic tractors and heavy-duty machinery, stands as a testament to this complex yet efficient system.

Image: mungfali.com

This article will delve into the captivating world of the Stanadyne DB4 injection pump. We’ll explore its key components, understand how they work together, and navigate the intricacies of a parts diagram, providing you with a valuable foundation for comprehending the mechanics of this crucial piece of equipment. Whether you’re a seasoned mechanic or simply curious about the inner workings of your engine, this guide will offer insight into the fascinating design of the Stanadyne DB4 injection pump.

Introduction to the Stanadyne DB4 Injection Pump

The Stanadyne DB4 injection pump is an integral part of the fuel delivery system in diesel engines. Its primary function is to precisely meter and time the delivery of fuel to the engine’s cylinders, ensuring optimal combustion and power output. The DB4 pump is a mechanical masterpiece, relying on a combination of gears, levers, and plungers to achieve its precise operation.

Understanding the various components of the Stanadyne DB4 injection pump is crucial for both troubleshooting and performing maintenance. Its complex design demands careful attention to detail, as even a minor malfunction can significantly impact engine performance. Let’s embark on a journey to unravel the secrets of this intricate system.

Key Components of the Stanadyne DB4 Injection Pump

1. The Plunger and Barrel Assembly

The heart of the Stanadyne DB4 pump lies in the plunger and barrel assembly. The plunger, a precisely machined rod, reciprocates within the barrel, creating a sealed chamber. This chamber houses the fuel, and as the plunger moves, it displaces the fuel, driving it towards the outlet port.

Image: rent-a-street.de

2. The Delivery Valve

Acting as a gatekeeper, the delivery valve controls the flow of fuel from the plunger chamber to the injector. The valve opens and closes based on the pressure difference between the plunger chamber and the injector line. This intricate mechanism ensures that fuel is delivered only when the injector is ready to receive it.

3. The Governor

The governor is responsible for regulating the engine’s speed. It senses the speed of the engine and adjusts the fuel delivery rate accordingly. This mechanism fine-tunes the fuel flow to maintain the desired engine speed, ensuring smooth operation across various loads.

4. The Timing Mechanism

The timing mechanism plays a critical role in synchronizing the fuel delivery with the engine’s cycle. It ensures that fuel is injected at the precise moment for optimal combustion. This mechanism is typically driven by the engine’s camshaft, ensuring accurate timing even as the engine RPM fluctuates.

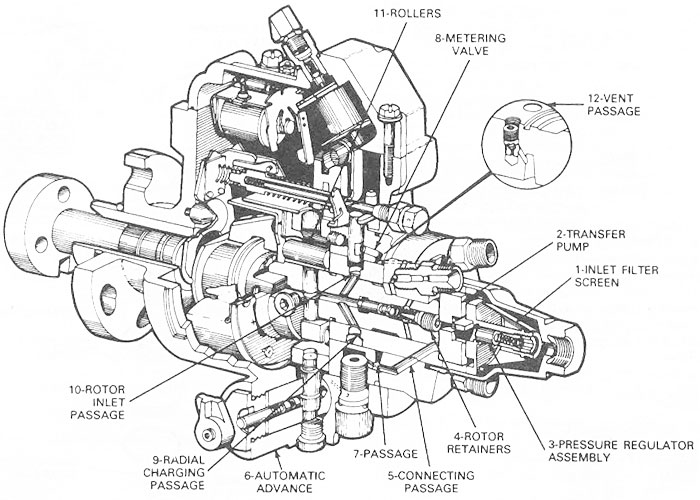

The Stanadyne DB4 Injection Pump Parts Diagram: Decoding the Visual Guide

Understanding a Stanadyne DB4 injection pump parts diagram is essential for navigating its complexities. This diagram acts as a visual roadmap, providing a detailed overview of the pump’s components and their relationships. Let’s explore the key elements of a typical parts diagram:

1. Component Identification

The diagram clearly labels all the critical components of the pump, with each part designated by a unique number or letter. These labels correspond to a legend, which provides a detailed description of each component and its function.

2. Assembly Relationship

The parts diagram illustrates how the various components are assembled and interconnected. Lines and arrows indicate the flow of fuel, oil, or other fluids within the pump. This visual representation helps you visualize the pump’s operational sequence.

3. Exploded View

Many diagrams offer an exploded view, showing the pump disassembled into its individual components. This allows for a clearer understanding of the layout and how the parts fit together. It also aids in identifying individual components during repair or maintenance.

Applications and Maintenance of the Stanadyne DB4 Injection Pump

The Stanadyne DB4 injection pump is renowned for its durability and reliability, making it a popular choice for various applications, including:

- Tractors: DB4 pumps are commonly found in classic agricultural tractors, delivering the power needed for demanding farm tasks.

- Heavy-Duty Trucks: These pumps contribute to the robust performance of heavy-duty trucks, providing the fuel efficiency and power required for long-haul transport.

- Construction Equipment: DB4 pumps are reliable choices for construction machinery, ensuring consistent power output even in demanding environments.

Maintaining a Stanadyne DB4 injection pump is crucial for ensuring smooth engine operation and longevity. Regular servicing includes:

- Fuel Filter Replacement: Clean fuel is essential for the proper functioning of the pump. Regularly replace the fuel filter to prevent contaminants from entering the system.

- Oil Change: Like any mechanical system, the DB4 pump relies on lubrication. Regular oil changes are critical for maintaining smooth operation.

- Injection Timing Adjustment: Proper injection timing is crucial for optimal combustion. Professional mechanics can adjust the timing to ensure peak performance.

Exploring Further: Resources and Additional Information

The world of diesel engine technology, particularly the Stanadyne DB4 injection pump, is vast and intriguing. If you’re eager to dig deeper, here are some valuable resources:

- Online Forums: Online forums dedicated to diesel engine enthusiasts and mechanics are treasure troves of information, where you can ask questions and participate in discussions.

- Repair Manuals: Stanadyne DB4 pump repair manuals provide detailed instructions, specifications, and troubleshooting guides.

- Technical Websites: Dedicated websites focusing on diesel engine technology offer a wealth of technical information, including tutorials, schematics, and parts catalogs.

Stanadyne Db4 Injection Pump Parts Diagram

Conclusion

The Stanadyne DB4 injection pump is a complex yet efficient marvel of engineering. Understanding its components, their functions, and the information contained within a parts diagram provides a valuable foundation for navigating the world of diesel engine technology. Whether you’re a seasoned mechanic or simply intrigued by the inner workings of your engine, this guide has equipped you with the knowledge to explore the intricacies of the Stanadyne DB4 injection pump. As you venture deeper into this fascinating realm, remember that continuous learning and exploration are key to unlocking the full potential of this powerful engine technology.